High-Precision Glass Optical Element

Plastic lenses and optical components are now used in a variety of fields taking advantage of its features, particularly high degree of freedom in shape, light weight, and high mass-productivity. However, glass optical elements, being physically and chemically stable, are essential for specific applications in very high-power density regions such as laser processing machines, in ultraviolet region where plastic does not work well, and in optical systems where high environmental durability is required.

Nalux also mass-produces glass optical elements by high-precision glass molding for optical fields in which plastic optical elements do not satisfy the requirements. We offer the optimum solution including the best material selection for your application and a combination of plastic and glass optical elements upon your request.

Features of Glass Optical Elements

- Small thermal expansion coefficient and small temperature variation

- High heat-resistant temperature, energy-resistant density, weather-resistance, and chemical-resistance

- A wide variety of material available for your refractive index and its dependence on wavelength

- Small water absorption and photoelastic constant

- Wide wavelength bandwidth (near UV to near IR)

Product Examples

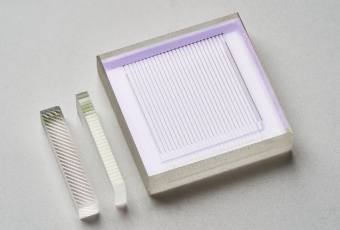

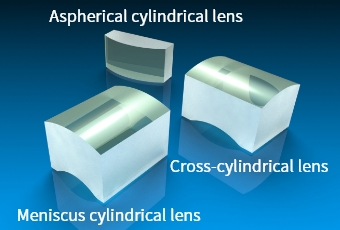

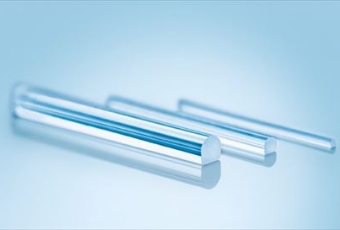

Glass Cylindrical Lens, Cylindrical Lens Array

A cylindrical lens refers to a lens which has cylindrical lens surface(s) and refractive power functioning as a lens only in one direction. Cylindrical lenses are used in a variety of applications, particularly fiber laser processing machines, LiDAR sensors and optical communications.

Key Features of Nalux Aspherical Cylindrical Lens

We have successfully established a unique method of manufacturing glass cylindrical lenses which allows us to achieve high precision, less variation and high productivity. The method is covering your mass-production needs even if the volume is more than 1 milion lenses a month*.

Glass lenses are highly heat-resistant, environmentally stable and light-resistant, which are ideal for applications required for high reliability and extreme temperature environment.

The established manufacturing method is well-suited for aspherical glass cylindrical lenses, which had been difficult to mass-produce with the conventional methods, as well as meniscus lenses, cross-cylindrical lenses, and cylindrical lens arrays.

What makes Nalux special is to listen actively to your requirements and propose design solutions optimized for individual cases. It is our pleasure to propose optimization which covers not only constraints on optical specifications or lens processing at our end but also pays respect to meet your process of manufacturing. Feel free to contact us for solutions.

*Production capacity is dependent on your specifications. For more details, contact us anytime.

Specifications Example

| Specifications | Range |

| N.A. | <0.5 |

| Focal length (EFL) | >0.15 mm |

| Material | All kinds of moldable glass materials (refractive index: approx. 1.5 - 1.8) |

| Lens length | 1 ~ 20 mm |

| Surface shape | Spherical, Aspherical |

| Lens shape | Plano-convex, Plano-concave, Biconvex, Biconcave, Meniscus, Cross-cylindrical, and Lens array |

| AR coating | 790 – 990nm, UV band, and Optical communication wavelength band, etc. |

If you have any requests other than specification shown above, please feel free to let us know.

Application Examples

Laser Processing Machine

Nalux has been supplying for more than 10 years our cylindrical lenses to be used as collimation lenses (FAC and SAC) of high-power laser diodes. For using a cylindrical lens as condenser lens into a fiber, we have improved coupling efficiency by corrected aberration as a result of changing to aspherical surface. A beam twister is also a kind of cylindrical lenses, enabling a laser diode bar to substantially improve its light condensing performance.

LiDAR

Glass cylindrical lenses also work well in LiDAR (Light Detection and Ranging), which are used as a space sensor in Advanced Driver-Assistance Systems and industrial equipment. The cylindrical lenses are used in a lighting system for beam collimating and beam shaping to a line beam. If a cover glass of a line sensor used in a light reception system is replaced with a cylindrical lens array, it will help improve sensitivity.

Glass cylindrical lenses are used in many other applications including optical communication, medical and industrial equipment, where users call for high reliability, heat and light resistance.

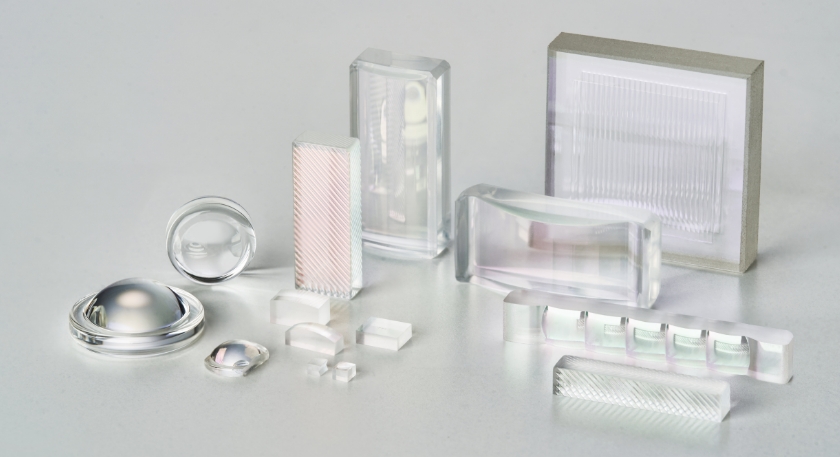

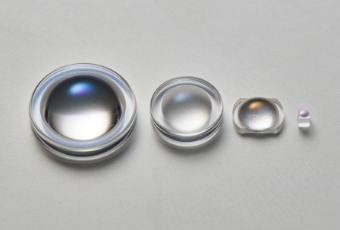

Glass Aspherical Lens and Lens Array

These are glass small aspherical lenses used for laser beam collimating, condensing and optical fiber coupling. Outer shape can be rectangular as well as circle. Superior in outer shape and lens positioning accuracy, small square aspherical lens is one of the ideal solutions to make optical modules compact. Our glass micro lens array has achieved 0.1μm or smaller guaranteed accuracy in distance between lenses (lens pitch).

We offer our glass aspherical lenses and lens arrays for the applications where high reliability and heat-resistance is required, such as industrial laser system and central optical communications. They are also well-suited to application for UV-LED (365nm~) due to high resistance to ultraviolet rays. Our glass optics are widely used for many other applications including optical communications, medical and industrial equipment.

Specifications Example

| Specifications | Range |

| NA | <0.8 |

| Material | All kinds of moldable glass materials (refractive index: approx. 1.5 - 1.8) |

| Outer shape size | 1 ~ 20 mm、φ3~30㎜ |

| Surface shape | Spherical, Aspherical |

| Lens shape | Plano-convex, Plano-concave, Biconvex, Biconcave, and Lens array |

| AR coating | 790 – 990nm, UV band, and Optical communication wavelength band, etc. |

If you have any requests other than those shown above, please feel free to contact us.

Application Examples:

- Optical system for optical communication

- Illumination optics using UV-LED

- Laser diode collimation

- High power laser condensing

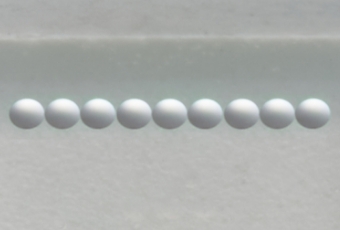

High Quality FAC Lenses

Fast Axis Collimator (FAC) Lenses are compact-sized aspherical cylindrical lenses. Each FAC lens has a high NA (numerical aperture) ideal for collimating in the fast axis direction highly divergent light emitted from a laser diode.

FAC Lenses are used in a wide range of fields from industrial applications to optical communication and biometric industries, including pumping module of fiber laser processing machines. We offer quite a broad and extensive selection of standard FAC lenses as well as customized lenses. Our standard FAC portfolio includes short wavelength of blue. Blue lasers attract particular attention on their suitability for processing metals including copper because they are strongly absorbed by metals. For specifications, lineup of standard FAC Lenses and their stock availability, feel free to contact us.

FISBA AG is one of the leading suppliers for FAC lenses in the world and manufactures all FAC lenses in their own factory in Switzerland. Nalux is the partner of FISBA AG for Japanese market, and we not only sell but also assure quality and provide customer support of FISBA products.

Key Specifications

| Focal length | EFL 150 – 1700um |

| Material | Glass with high refractive index n>1.8 |

| Wavelength | 430 - 1550nm |

| Length | 2 - 20mm |

Key Features of FISBA FAC Lenses

- Large portfolio of standard FAC lenses

- Fast ramp-up from prototype to serial production

- Customized coating design by FISBA

Example Applications

- Diode laser systems

- Fiber laser pumps

- Disk laser pumps

- Solid-state laser pumps

- LiDAR systems

FAC Lenses on Bottom Tabs

The FAC Lens is an optical element which has so short focal length and so large NA that highly precise positioning on the sub-micron level is required in assembling.

On the other hand, the FAC Lens is so small and difficult in handing and gluing. High technology is required in handling. FISBA FAC Lenses are available with optional bottom tabs allowing easier handling and gluing.

FAC Lenses are positioned on the tabs with high precision (±2um). Glue stop, a structure preventing glue from spreading to non-glue area, can be added. Tabs also allows FAC smile to be reduced and controlled.

Benefits with FAC Lenses on bottom tabs

- Easy handling on tabs

- Controlled FAC smile / FAC smile on low, stable level

- Precise positioning on tabs (± 2 μm)

- Adjusted offset of the FAC to the tab, depending on the individually measured BFL of the lens (+/-5µm).

- Constant glue gap in your application

Optional glue stop

* These are the products of FISBA AG, an alliance company with Nalux.