We deliver high quality, high precision, cutting edge manufacturing with our "Turn Key" solution.Nalux creates future of optics together with our customers.

We can provide "Turn Key" solution from optical design to final products depending on our customer's requirements. We have supplied various optical products such as lens, mirrors, DOE(Diffractive Optical Element), Optical Modules to various market from enterprise products to consumer products.

Why NALUX?

01Cutting edge lens development

Our vision ”Lighting a path to the future with nano-optics".

We pursue advanced light and process technologies in relentless manner.

We pursue trail blazing optical and processing technologies in reletless manner by engaging joint research with highly accredited academic institutes in Japan and overseas and between industry and academia.

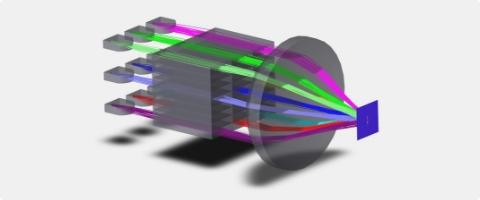

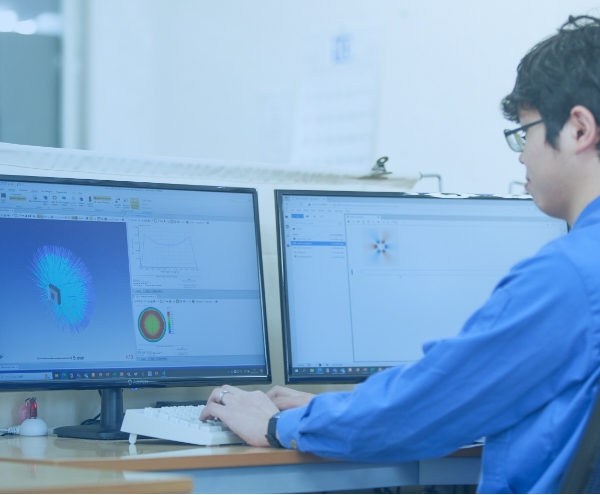

02Outstanding Optical Design Capability

We provide our supports to our customers realizing "product" from optical design.

We, Nalux are able to support our customers from optical design phase in addiiton to volume production of optics. We have extensive number of experienced optical engineers in our team, who have made various kinds of optical designs and proposals to our customers for a long period of time such as imaging, illumination and scan optics. We provide thorough supports to our customers in order to help them realizing customers' products. We also are able to provide optical design supports for DOE (Diffractive Optical Elements), CGH (Computer Generated Hologram) based on wave optics with Nalux's self developed optical design tool.

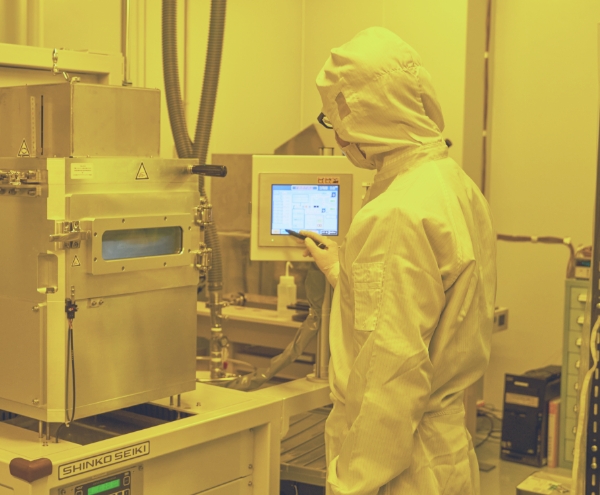

03Tool processing in pursuit of ultimate accuracy

Ultra precision, high quality and high reliability as a world leader

In addition to state of the art ultra precision process machines, we make tireless efforts to advance tool processing technologies including joint-development of technologies with processing machine manufacturers. We are also able to handle processing very fine structures, smaller than light wave-length by electron beam lithography technologies. Our simulation capabilities such as mold flow, temperature and structure analysis enable us to predict potential defects in production. As the result of those, our team can work out optimum designs by front loading at early phase of the project.

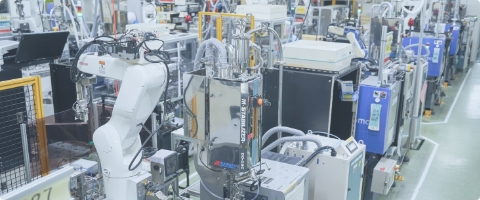

04Production technology to enable consistent quality.

24/7 stable mass production by automated production line and real time monitoring.

24/7 complete automated production from molding to packaging. We manage our production line with data collected from tools, molding machines, peripheral apparatus, in-line inspection and metrology equipment. We have established stable production system and let them keep functioning appropriately by capturing the signs of changes from data collected, to minimize defects.

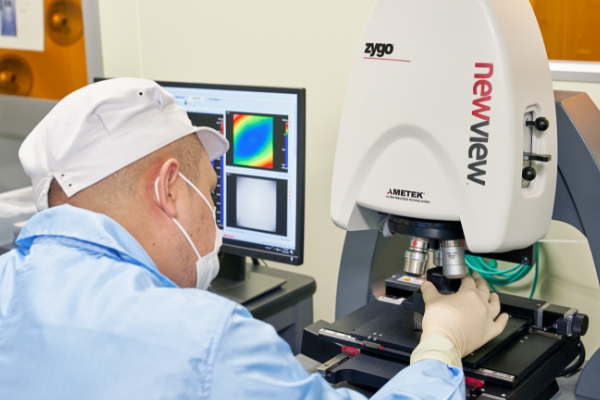

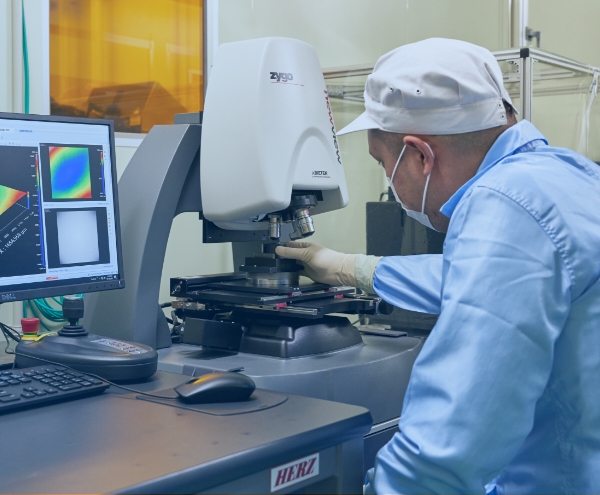

05Reliable quality assurance system

Stringent quality assurance system to backup high precison manufacturing.

State of the art metrology system is indispensablein order to ensure high precision product quality in addition to advanced tool processing and production technology.

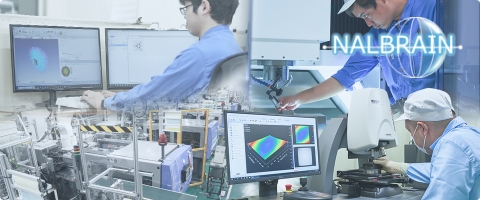

06One stop shop for optics

Nalux's "One team" spirit and system enables to establish trustworthy partnerships with our customers.

We're "One stop shop" for optics from R&D, design, manufacturing and quality assurance taking care of all processes in-house. We're builiding our self-made system called "NALBRAIN" which manages real time production data and collecting and sharing technical know-how and technologies as our cross functional team.

4 core technologies supporting Nalux

Inquiry Flow

Please feel free to contact us via inquiry forms or calls. We welcome to hear "What you want to achieve" even without any drawing or specifications.

Our sales representatives will get in touch with you. They'll be eager to listen to your needs and/or requests in order to perform initial feasibility study.

Our "Team Nalux" experts in various fields work together for the feasibility study based on information shared by you.

We'll propose a meeting with you based upon our internal study. Our team will try to truly understand your requirement and make the most optimised proposal in meeting as needed.

Our team puts together our drawing, specification and quotation based on agreed to contents.

We expect our customers to release PO once they consent on our specification and quote.