Initiate develpment of ultra fine processing in nano meter level

―Aim to create new businesses with new surface structures applying high precision optical elements and biomimetics―

What is Ultra precision fine surface processing?

This is intended to provide various optical and physical functions via very fine structual patterns smaller than wave length of light created on the surface of products or tools.

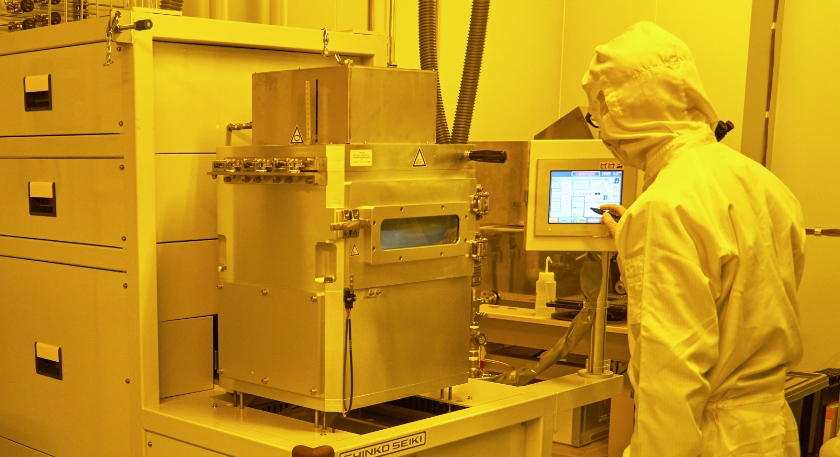

Nalux's Lithography technologies

Nalux has been working hard on R&D of ultra fine surface procesing best utilizing various equipments such as Nalux's own in-house lithography equipment and also external semiconductor processing equipments available at Fine Processing Platform of Center for Integrated Nano Technology Support located in Tohoku Univ.

Nalux is aiming to develop new businesses by R&D works applying biomimetics which is copying surface structures of living things, enabling to provide surface characteristics such as Anti-reflection and Water repellency function.

Examples of lithography process

Photoresist patterning

- Exposure with Photo mask

- Laser Drawing

- Electron beam drawing

Shape transfer

- UV imprint

- Electroforming

Etching

- Plasma etching

- Wet etching

Thin film formation

- Spattering

- Lift-off process

ARS(Anti-Refective Structure)

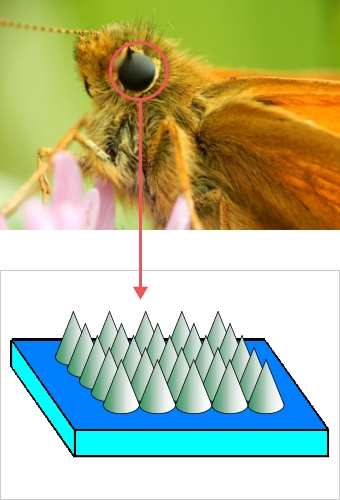

Moth eye has very fine peaks and troughs structures which have functions to suppress reflection of light. Thus structure is called ARS (Anti Reflection Structure). Conventional method to achieve anti-reflection function on optical part is to apply coating by vacuum deposition, while ARS generated by fine surface processing has advantages such as low incident angle dependence of light, no delamination or cracks of coating in principle and applicable even for the poor coating adhesion lmaterials like PMMA.

Nalux has been working on developing process technologies of creating ARS on lens surface.

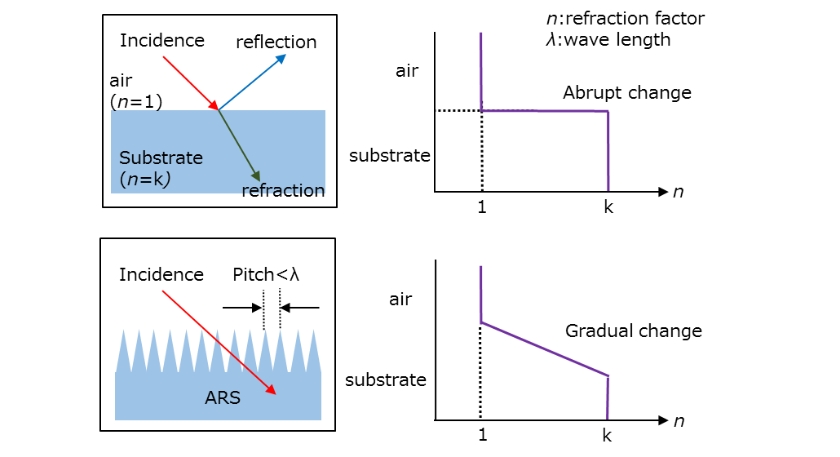

How it works.

Reflection of light is caused by drastic change of refractive index, for example when light enters lens from air. Reflection of light is suppressed when lens has structures which are smaller pitches than wave length of light on its surface, because those structures help to make refractive index change smoother.

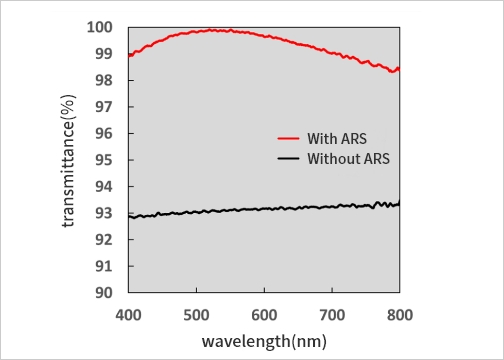

Nalux's ARS characteristics

- Improved shape transfer of moth eye structures on lens by changing to concave profile from convex one (US Patent No.11/921,324 granted)

- Unique processing (PAT 5584907 granated) which enables to tranfer moth eye structure on curved and large area. Track record: 60mm diameter.

- Optimized structure design feasible by using Nalux's unique optical design software developed in house.

- RIE(Reactive Ion Etching) technology applicable for direct processing on lens (JP-Patent No. 6611113, No. 6901189).

RIE application and processing examples

- Suitable for illumination lens used under direct sunshine and automobile applications requirng high reliability;

- Imaging and Sensor system

- Lens product which requires dust proof characteristic such as medical endoscopes

Application to optics having high dependency on incident angle of light :

Substrate materials: Silicon, Polycarbonate, Acrylic, Fused silica, etc.

Our track records on various materials:

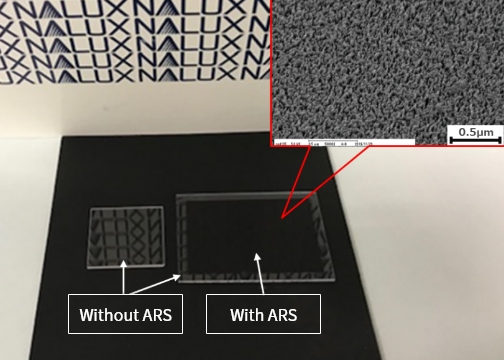

ARS processing example on fused silica:

You see no reflection on fused silica with ARS on the right while you see reflection of "Letters on the wall" on the fused silica without ARS on the left.

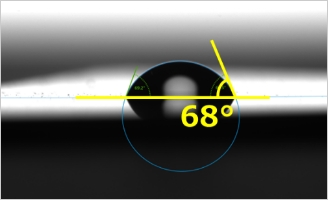

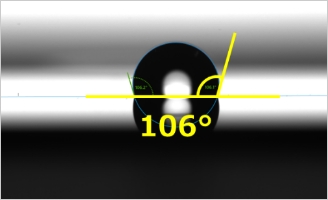

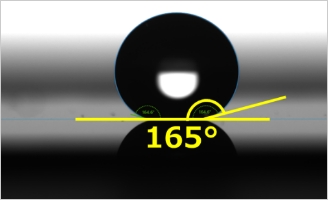

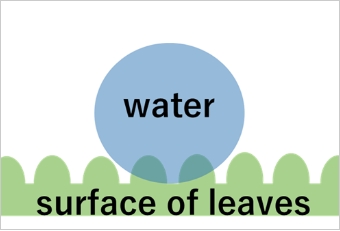

Ultra hydrophobicity property (water repellency) achieved by using the ARS

Technology to generate fine structures like ARS on the lens surface is applicable to control wettability of the material surfaces. It is widely known that lotus has water repellent leaves , so called "lotus effect" in nature. This effect is achieved because concave and convex structures on the leaf surface enhance water repellency or hydrophobicity.

We can thus control wettability by fine structures taking advantage of lotus leaf effect.

One advantage is that we can provide hydrophobicity property by etching process direct on lens surfaces to materials not suitable for conventional water repellency process such as vacuum deposition or spraying. Another advantage is to provide antifouling effect on the lens.

Other application example: Black Silicon

Hydrophobic property becomes much stronger if water repelency coating is done on substrate having micro fine structure rather than a flat smooth substrate.

At Nalux, we achieved remarkably large contact angle of over 160 degrees(In general contact angle over 150degree is called "Ultra water repellent status".