Diffractive Optical Element (DOE)

A Diffractive Optical Element (DOE) is an optical element which utilizs the diffraction phenomena of light. The general optical element like lenses controls the light such as focusing and diffusing by using the refraction of light at interface caused by the refractive index difference between air and optical element. On the other hand, DOE controls the light direction and intensity utilizing the diffraction pheonmena caused by the micro structures on the surface of the optical element. DOE can be used for a lot of applications. For example, it is used for a pattern generator to generate any desired diffraction image as Computer Generated Holograms (CGH), a beam shaper to change beam shapes of the laser beam, a spot generator to create many bright spots from a laser light, and giving optical functions on optics like chromatic aberration correction or temperature compensation.

Characteristics of NALUX Diffractive Optical Elements

We can:

- design and propose optimized CGH shapes using self-developed design software.

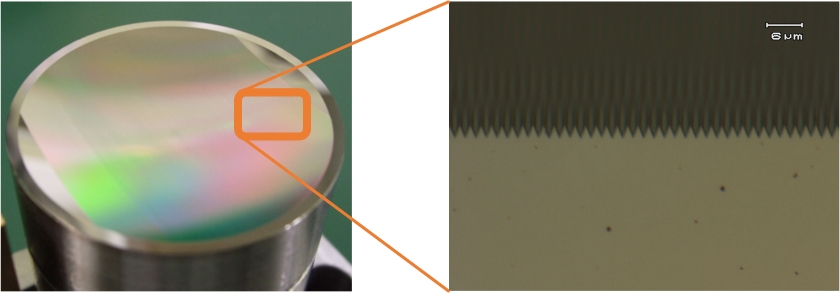

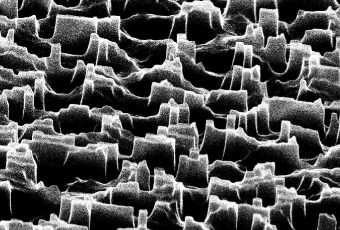

- design and mass-produce various profiles of diffractive structures like blazed (saw tooth shape) and staircase shape.

- design and process multi-level (multi steps) pattern.

- create diffractive structures on both surfaces of optical element

- directly process DOE on fused silica and also mass-produce the optical element by plastic injection molding.

- measure optical functions, such as spectro intensity and diffraction efficiency by self-deveoped functional measuring instrument in order to gurantee the quality.

Application examples DOE is applicable

- Amusement devices, Home appliances, Medical devices, Autotmotive, Robot etc.

(Applying DOE for motion capturing and AR/VR.) - Beam shapers and spot generators for laser processing equipment and communication devices and spectroscope etc.

(Applying DOE for beam shaping, spot generating and spectroscope.)

Actual DOE Application examples

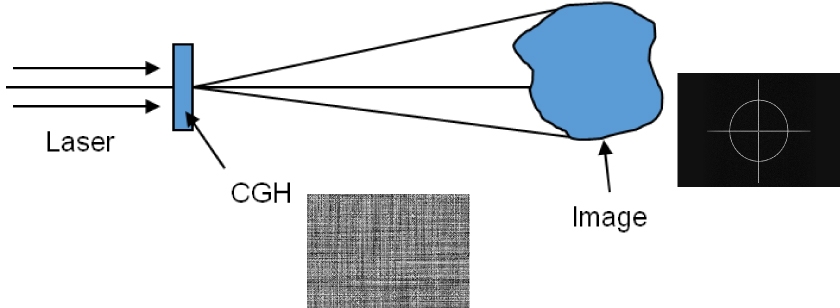

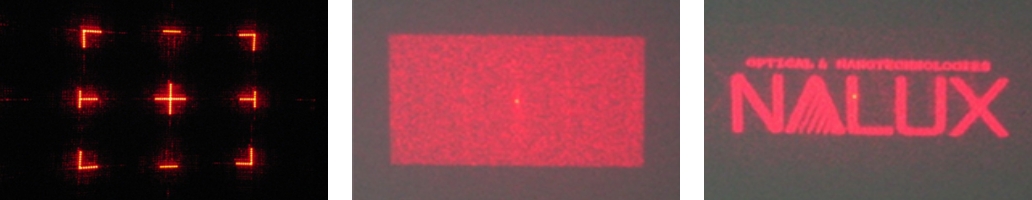

Computer-Generated Hologram (CGH)

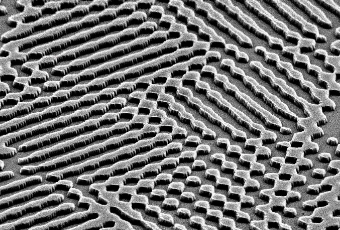

Hologram is an optical element recording the interference fringes (2D phase information) generated by the ineterference between object light and reference light. Applying appropriate light to the hologram, the recorded object light image can be regenerated. on the other hand, CGH is an optical element created by calculating the phase information forming the desired diffractive image and modeling it as concave-convex structures. Applying the certain light to to such a CGH, the calculated diffractive image can be regeneraged. CGH is generally fine and very complicated structures. NALUX can produce various CGH products by our ultimate micro processing technologies like electron beam lithography and ultra precision injection molding.

Characteristics of NALUX CGH:

- Advanced optical design taking ghost and distorsion correction in to consideration by self developed design software.

- Fabrication of highly accurate microstructures by lithography technology using EB and etching.

- Materialization of sharply illuminated pattern by high transfer molding technology.

CGH Application examples:

- Pattern generators and target markers for barcode scanners in retail/logistics, attractions, and industrial devices

(Applying CGH for pattern generator and target markers.)

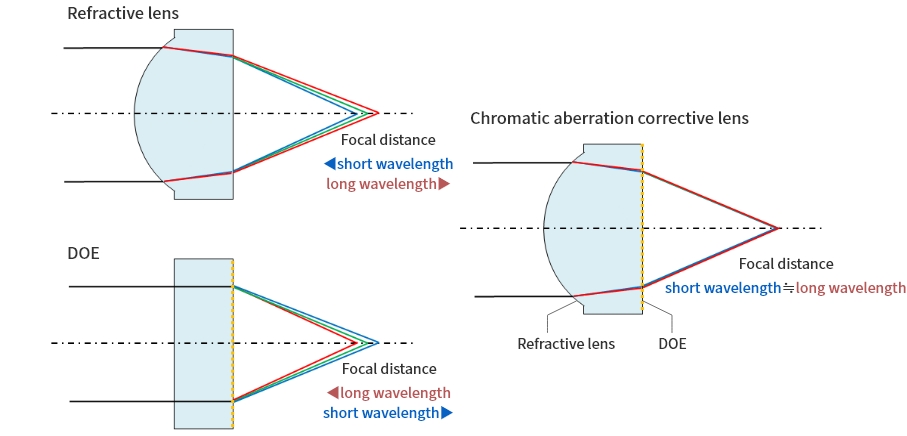

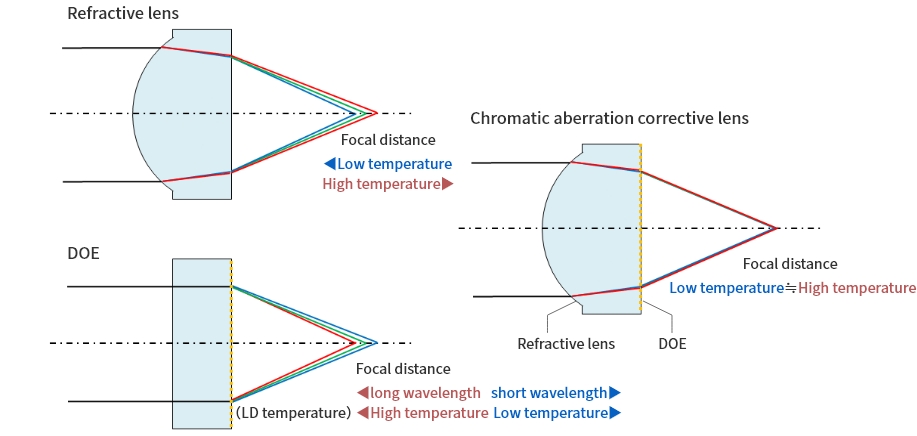

Chromatic aberration correction by DOE

The refractive index of the optical materials increases with shorter wavelength in and near the visible light range. So, for example, in the case of a condenser lens, the focal length varies depending on the wavelength and it's getting shorter with shorter wavelengths (Positive dispersion). In order to compensate this color aberration, it's well known to combine with a convex lens with small dispersion and a concave lens with large dispersion. However, the disadvantage of this method is that the number of lenses increases. On the other hand, a larger light diffraction angle can be obtained at longer wavelengths with a corrective DOE, depending on DOE structures (Negative dispersion). In other words, chromatic aberration can be corrected by combining a refractive lens and a corrective DOE structure and it can contribute to reduce the number of lenses. DOE structures can be applied on the flat surface of flat-convex lens and on the curved surface of the lens.

Application examples in actual use:

- Chromatic control of light distribution for head light lens

- Optical pick up lens

- Small imaging lens for mobile phone requiring high resolution

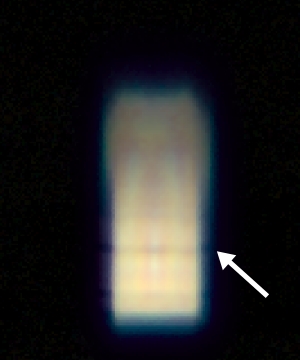

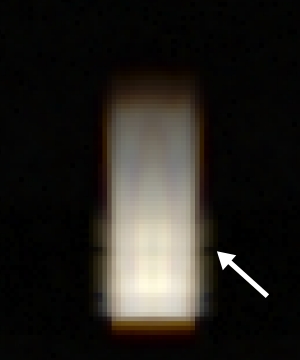

Example of Chromatic aberration improvement: Comparison on illumination pattern of LED lighting

Without DOE

With Chromatic aberration correction by DOE

Color control of light distribution by applying DOE (New Technology/Product Award at the 27th Small and Midium Enterprise Exhibition)

Related Patents

- Patents related to automotive headlight

- ・JP5315505

- ・JP5909419

- ・JP6849193

- Patents related to small imaging optics

- ・JP4317933

- ・JP4992004

- ・JP4798529

- ・JP4822033

- Patents related to pick-up optics (single objective lens for 3 wavelengths used for CD, DVD, and BD)

- ・JP4649572

Temperature compensated collimator

Temperature variation of refractive index in optical properties is one of the challenges in plastic lens design. For example, the refractive index decreases and the focal length increases as the temperature of the lens increases in collimator lenses used for laser beam printers. NALUX has materialized temperature-compensated optics by utilizing the temperature dependence of laser diode emission wavelengths and the characteristics of diffractive optical elements. This optical system suppresses focal length fluctuations of plastic lenses due to temperature by utilizing the characteristics of LD that the oscillation wavelength becomes longer as the temperature rises, and the characteristics of deffractive optical elements that the diffractive power becomes stronger at longer wavelengths. in this way, NALUX believes that it is possible to make better design proposals not only for the optical elements produced by us but also by understanding the entire product, including the light source, detector, assembly, usage, and application and by performing overall optimization by taking their characteristics into cosideration.

Application examples in actual use:

- Incident optical elements for laser beam printers (collimator and cylinder lens) and optical elements which has problems on operating temperature rgange.