Supporting the Future of Healthcare with Optical Technology and Precision Processing

As a specialized manufacturer of optical components, Nalux leverages advanced optical design, precision processing, and mass production expertise—cultivated over decades in various market such as industrial equipment, automotive, and optical communications—to address the evolving demands of the medical field. Our integrated system from optical and product design to full-scale production enables us to deliver customized solutions for a wide range of medical applications, including endoscopes, diagnostic devices, bioanalytical systems, and research instruments. While our core strength lies in optical components, we also support precision parts and components requiring exceptional precision or specialized properties, such as heat and chemical resistance.

Our Value to the Medical Industry:

- Optimization of both performance and cost through strategic selection of diverse materials (plastic, glass, and more)

- Expertise not only in optical components, but also in compact, high-precision parts and molded plastic or glass components with excellent heat and chemical resistance

- High quality and environmental compliance required for medical applications (achieved through clean production systems and traceability) as well as a stable, long-term supply system

- Flexible production systems to support everything from prototyping to full-scale mass production

Examples of Medical Applications

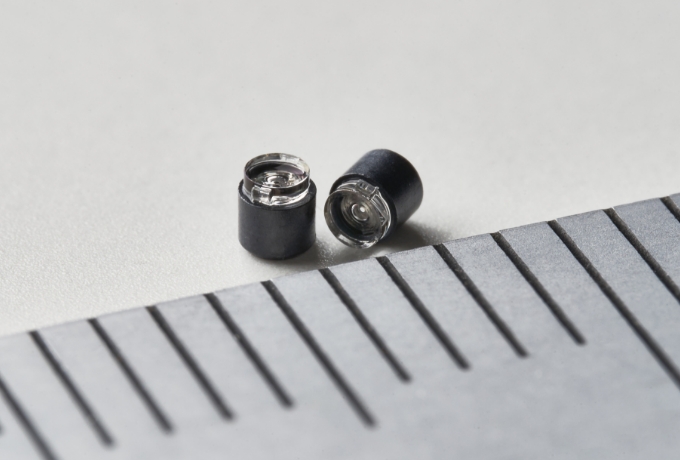

Plastic Lens Units for Disposable Endoscopes

These compact, high-quality lens units utilize aspheric plastic lenses, offering superior mass-production efficiency and making them ideal for single-use applications compared to conventional glass lenses. In addition to applications in ultra-thin endoscopes, they can also be embedded in treatment instruments for real-time monitoring of treated areas or integrated into wearable devices for imaging purposes.

Typical Applications

- Disposable endoscopes

- Integration into treatment instruments for monitoring during treatment

- Incorporation into wearable devices for image capture and recognition

- Visual inspection and quality control of small-diameter tubing interiors (e.g., verifying cleaning effectiveness or product quality of medical devices)

Example Specifications

| Material | Resin |

| Lens diameter | φ1.3 mm |

| Unit size | φ1.3 mm × 1.37 mm |

| Field of view (diagonal) | 120° |

| F number | 6 |

| Focal length | 0.570 mm |

| Object distance | 3-200 mm |

| MTF@140Lp/mm Image Circle |

Center > 40% |

| Periphery(Image height 70%) > 35% | |

| φ1.0 mm | |

| Operating temperature | +12℃ ~ +40℃ |

Image Sensor Used: Omnivision CMOS sensor OV694

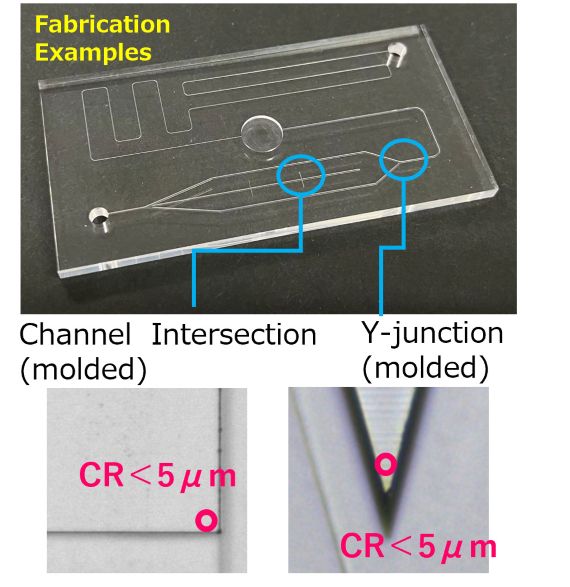

Microfluidic Channels

Microfluidic channels are microscopic grooves or fluid pathways—typically ranging from several tens to several hundreds of micrometers in width and depth—used in microfluidic devices, biochips, and lab-on-a-chip systems. These channels enable precise control and manipulation of minute volumes of liquids or gases, supporting applications in medical diagnostics, chemical analysis, cell manipulation, and more.

Advantages of High-Precision Fabrication

The performance of microfluidic channels depends heavily on the accuracy of their shape and dimensions. Leveraging advanced precision fabrication technologies offers several key benefits:

・Precise reproduction of channel width and depth enables accurate control of fluid velocity and flow rate

・Minimizes product variation and enhances reliability

・Supports complex channel designs such as bends, branches, and mixing structures, enabling multifunctional device capabilities

・Optimized fluid flow improves the efficiency of chemical reactions and enhances the sensitivity of biomolecular detection

High-precision microchannel fabrication is therefore a critical factor in enhancing device performance and reliability and plays a key role in advancing cutting-edge technologies.

At Nalux, we have cultivated submicron-level fabrication capabilities through our long-standing experience in optical component manufacturing. Because optical components demand tighter tolerances and stricter contamination control than typical molded plastic parts, we have established rigorous dimensional accuracy and quality assurance standards.

Leveraging this submicron-level precision, we are able to support the production of molded plastic components that require exceptional accuracy and functionality. We are committed to delivering high-value solutions that meet diverse customer needs.

Superhydrophobic / Superhydrophilic Surface Processing

The surface of a lotus leaf features micro-scale textures that prevent water from spreading across it. Instead, water forms droplets that roll off easily, carrying away dust and dirt, which is known as the self-cleaning effect. At Nalux, we apply this effect by using advanced surface microfabrication techniques to impart superhydrophobic or superhydrophilic properties to plastics and glass products.

Application Proposals

- Improved liquid separation at pipette tips, enhancing usability and efficiency

- Enhanced throughput of chemical solution, enabling more efficient utilization

- Prevention of contamination on components exposed to liquids

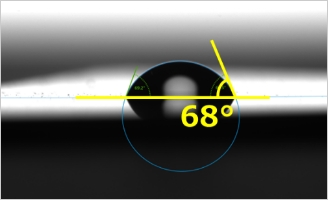

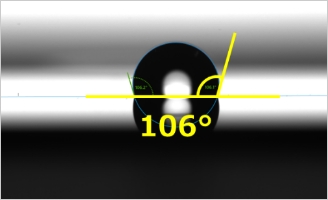

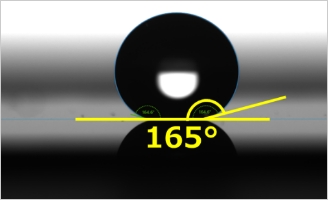

Case Study: Superhydrophobic Coating on Silicon Substrate

While surfaces with contact angles above 150° are generally classified as superhydrophobic, our ultra-precise microfabrication technology has enabled us to achieve contact angles exceeding 160°.

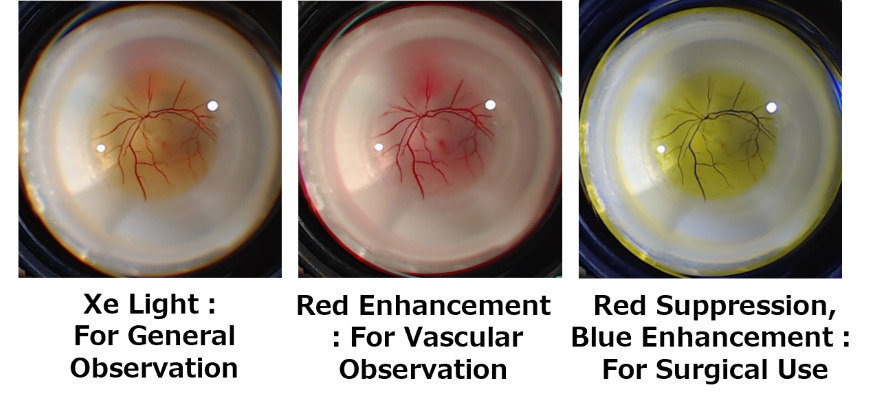

SCOI (Spectral Characteristics Optimized Imaging)

SCOI is an advanced light control technology that enhances what we want to see while reducing visibility of unwanted elements. The color we perceive from an object is determined by three factors: the spectral distribution of the illumination, the object’s spectral reflectance, and the color matching functions, which represent the human sensitivity to different wavelengths . Of these, only the spectral distribution of the illumination can be actively controlled. The other two are fixed: the object’s spectral reflectance is a material property, and the color matching functions are determined by spectral sensitivity of the human eye during visual observation. While wearing colored glasses can control the functions, it comes with drawbacks such as fogging and the inconvenience of taking them on and off. SCOI offers a smarter solution by adjusting the illumination’s spectral distribution, allowing control over how colors appear. Moreover, by optimizing the spectral distribution of illumination, SCOI can alter color perception while preserving a white light appearance, reducing visual strain during extended observation.

In medical applications, SCOI is being developed to reduce the burden on both surgeons and patients by enhancing the visibility of specific tissues, such as making stained tissues stand out more clearly or suppressing the redness of blood to improve contrast in tissue contours.